Mechanical Seals

Textile Plant Mechanical Seals

Textile Seals are widely used in Textile plants. The “Micro Seals” Designed various types of Textile Mechanical seals for used in yarn & fibre dyeing plants,cloth dyeing application plants & high speed jet dyeing plants. The Textile Seals are non-clogging and self cleaning which make them suitable for use in various applications. Our Textile seals Generally used for Diaphragm Elastomer to Normal pressure machine like a mercerizing machine & pretreatment machine (Benninger – Make)

Distillery Mechanical Seals

We Stock Standard series of various types of food product’s mechanical seals, for standard pump like a Alfa Level FM, GM, EM, LKH10, ALC2, ALC3, Fristum pump, Zutech pump, G.D. & IDMC pump, of different types of food application.

Compressor Mechanical Seals

Compressor seals used on toxic and/or flammable gases, or when the process is contaminated with particles. The seal supply gas is maintained at a pressure higher than the pressure of the gas being sealed, which isolates the process gas from the atmosphere.

Waste water Pump Mechanical Seals

Water Pump Seals is a compact, single-spring, elastomer bellows mechanical seals. Water Pump seals are designed for use in small centrifugal water pumps, deep and shallow-well jet pumps, swimming pool pumps, submersible pumps and waste water pumps.

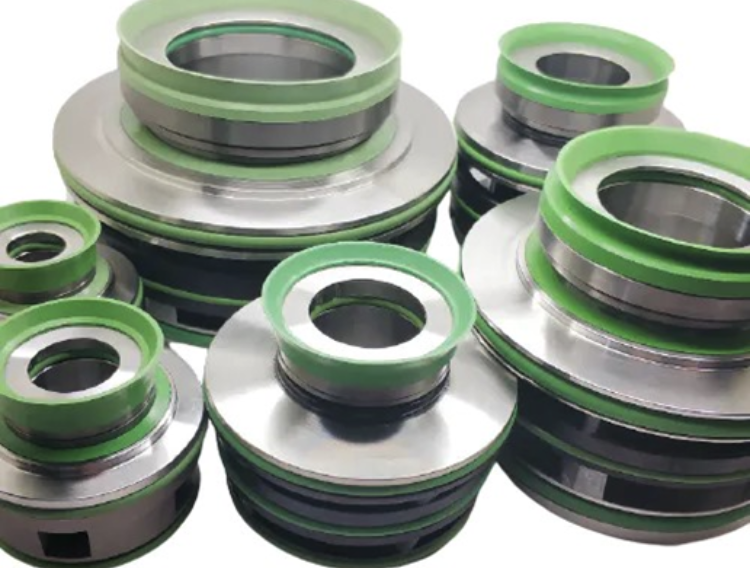

Metal Bellow Seals

Metal Bellow Seals are widely used in high temperature and highly corrosive media and suitable for high start-up torque since the bellows unit is independent of torque transmission. The unique feature of Metal Bellow Mechanical Seals is that, there is no dynamic ‘O’ rings and therefore it will never hang up or damage the shaft and sleeve. Application- Generally used for handling highly corrosive chemicals, high temperature applications and Hydrocarbons In Petrochemical industry, petroleum refinery , Paper & Pulp industry

Teflon Bellow Mechanical Seals

Teflon PTFE Bellow Seals are designed to handle highly corrosive liquids. PTFE Bellow seals are outside mounted with simple installation procedure and hence cost effective for corrosive media sealing. Teflon Bellow Mechanical seals has been designated as Fixed & replaceable bellow face respectively.For replaceable version there is flexibility for selection of face material as per the media to be sealed, which can be easily removed & replaced.

Rubber Bellow Mechanical Seals

Rubber Bellow Seals are mainly use in wastewater treatment plants for the sewage applications. Due to its compact design it can be easily mounted. It has a unique rubber bellow secondary seal, which provides a high degree of axial flexibility and protects the shaft/ sleeve from fretting.

MECHANICAL SEAL G1

Elastomer Bellow Seals has been designed for general sealing purpose which includes easy installation of the seal. Elastomer Spring seals used for water and sewage containing slurries. Shaft run out is compensated by Elastomer bellow and spring due to its self aligning capability.Elastomer Bellow protect Shaft/Sleeve from Fretting.

MECHANICAL SEAL G12

Elastomer Bellow Seals has been designed for general sealing purpose which includes easy installation of the seal. Elastomer Spring seals used for water and sewage containing slurries. Shaft run out is compensated by Elastomer bellow and spring due to its self aligning capability.Elastomer Bellow protect Shaft/Sleeve from Fretting.

MECHANICAL SEAL G13

Elastomer Bellow Seals has been designed for general sealing purpose which includes easy installation of the seal. Elastomer Spring seals used for water and sewage containing slurries. Shaft run out is compensated by Elastomer bellow and spring due to its self aligning capability.Elastomer Bellow protect Shaft/Sleeve from Fretting.

Balanced Spring Mechanical Seals

Multi Spring Balance Seals are pusher type balance multiple spring mechanical seals generally used when high pressure sealing required. Balanced Spring seals are compact in design suiting all types of rotating equipment’s – pumps and mixers. Drive lugs in the retainer will provide torque transmission and reduce slippage on shaft and sleeve

Capsulated Spring Balanced Mechanical Seals

Capsulated Spring Seals are a cost effective version of a Balanced seal They feature the same rugged and reliable construction as the Multi spring unbalanced seals. capsulated Balanced seals designed for media containing solid slurry particles. The springs are protected from solidifying media resulting in high reliability of the seal. This seals are independent of direction of rotation

Reversed Balanced Mechanical Seals

Multi Spring Reversed Balance Seals are external mounted multi coil spring Seals. Liquid pressure is used to close the Seal faces therefore very effective in high pressure and vacuum applications. The unique feature of Pusher Type Reversed Balanced Seals is that, it eliminated the shaft step or sleeves for balancing. It can be extremely useful for contaminated and light corrosive liquids as metal parts do not come in contact with media

Single coil Balanced Mechanical Seals

Single Spring Balanced Seals especially designed to suit Slurry Media Sealing,light contamination, dirty media and clogging type application. This type also allows it to fit onto a normal shaft without any balancing step. The mechanical drive of this seal is realised by grub screw which lock onto the shaft.

Single Spring Unbalanced Mechanical seals

Single Spring Unbalance Seals is unbalanced single acting helical coil spring seals independent of direction of rotation. single Coil unbalanced seals are internally mounted and easy to install.rotary seal ring is driven by the motion transmitted by the shaft to the spring.slippages are eliminated, protecting the shaft and sleeve from fretting

Conical Spring Unbalanced Mechanical Seals

Conical Spring Seals is single conical spring, unbalanced seal with O-ring provided for secondary sealing. Since the Torque transmission is done by the single coil springs the seals are dependent on the directions of rotation, which is seen from the drive end of the shaft.

Single Wave Spring Mechanical Seals

Wave Spring Seals are internally mounted which are non-clogging. They are designed for high viscous, abrasive media and are universal application and the spare parts are interchangeable without modification. Seal faces are easily inserted. They can be designed in which spring is isolated from pump media.Torque transmission from retainer shell to seal ring is through drive pin.

Flygt mechanical seal

The flygt pump seal is designed with the upper seal and lower seal. By using the Tunsten carbide, Tungsten carbide, and viton, the upper and the lower of the seal can be fitted smoothly, which ensures low leakage rates. When being operated in a controlled environment, the upper seal offers very high resistance. As for the lower seal, it features sturdy design and should be able to cope with fibrous clogging matter, hard abrasive particles, and chemically aggressive media, etc.

Grundfos mechanical seal

We 100% follow original and exquisite seal design concept to make sure the perfect performance applied in the machines. Precise and advanced machines are purchased for ensuring the width, height, thickness, and diameters of each part, or it may cause mechanical breakdown to a certain extent. Stainless steel is the main material adopted for the sealing frame, sealing joints, and so on, which is for the rust resistance and corrosion resistance of the product.

Cartridge seals

Cartridge seals are self conantainered units consisting of a shaft sleeve, seal, and gland plate. The unit is fitted onto the pump shaft as a built assembly, and no further fitting is required. Cartridge mechanical seals are an attempt to over-come the fitting problems of conventional seals. They are supplied in single and double form, and the gland plate is often fitted with various tappings to provide for flushing, cooling water injection, and disaster control.