Coupling

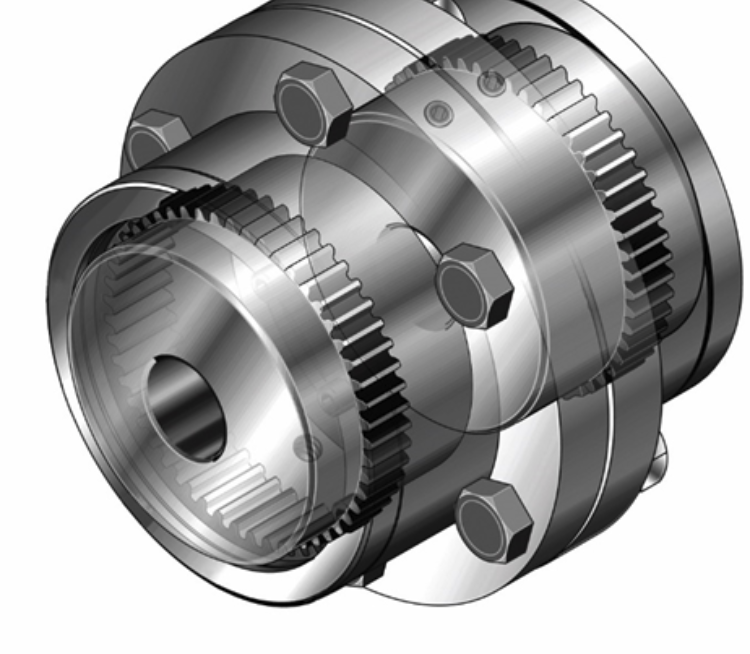

Gear Coupling

Gear couplings are mechanical devices that are used to join transmit between the two non-collinear shafts.

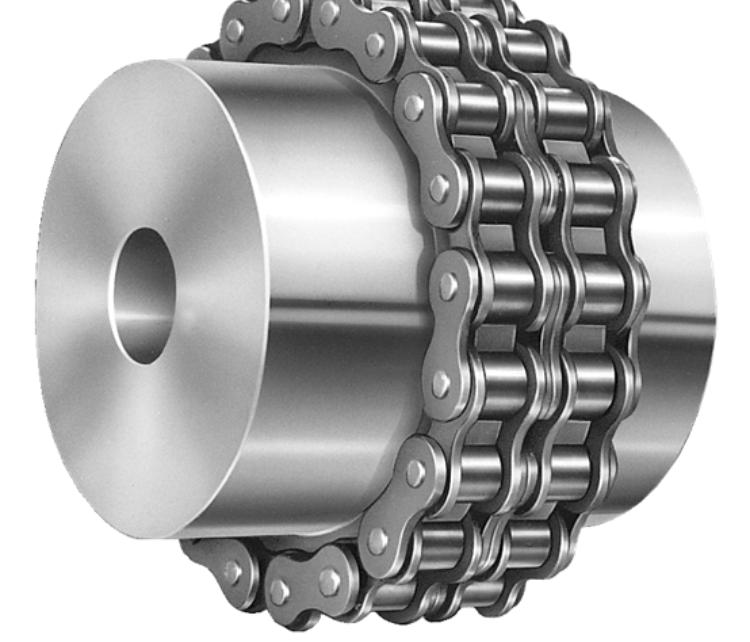

Chain Coupling

Chain Couplings are one of the oldest method of joining two rotating shaft with no transmissions loss.Chain Flexible Couplings are compact, all steel, long lasting flexible couplings, capable of transmitting relatively high torques with minimum of space consumption.

HRC Coupling

HRC couplings bear a smooth finish and texture. These types of couplings are influential in power transmission drives. These couplings are created using high-grade stainless steel that offers heavy resistance to corrosion.

SW Coupling

SW couplings are vital in pipe fitting applications where the pipes are made to fit permanently. These couplings have a smooth finish and are highly leak-proof in operations. SW couplings ensure the optimal flow of liquids and gases through the pipes.

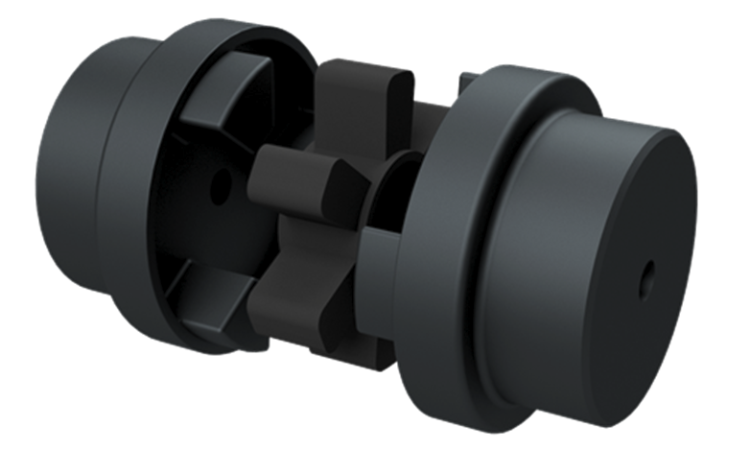

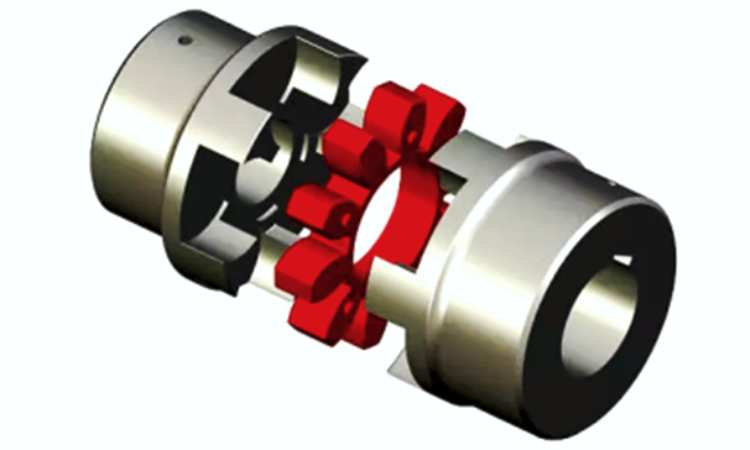

Spider Coupling

Spider couplings are framed using highly qualified raw materials that bear high tensile strength to resist heavy workloads. Spider coupling bears a smooth finish and texture that can be easily fitted in the industrial framework it is required for. Spider Flexible Couplings are vital in power transmission drives.

Rigid Coupling

These couplings bear a smooth finish and texture that is suitable to be installed in all types of industrial frameworks without any hassle. Rigid couplings are fabricated using high qualified raw materials that provide great strength to work flawlessly throughout their service life.

RRL Couplings

RRL couplings are power transmission couplings that are used in motion control applications and are sufficiently designed to offer high torque connecting the two shafts. These are applicable in various mechanisms to prevent them from misalignment.

RRS Coupling

RRS coupling is specifically designed to present the torque between the shafts of the power transmitter. RRS couplings have easy elastomer installation and are structured with universal quality standards. RRS couplings are high-grade raw materials such as glass-reinforced plastic, cast iron, or aluminum.

Nylon Gear Coupling

Nylon couplings have two steel hubs that have a compact structure and no lubrication is required for hassle free operation. Nylon coupling operate over the max temperature range of speeds up to 5000 RPM.

Encoder Coupling

Encoder Coupling Provides Electrical Isolation and Maximum Mechanical Protection of Encoder Shaft Connections. The coupling is a mechanical element that connects two shafts together to accurately transfer power from the driving side to the driven side, compensating for mounting errors (misalignment), etc. of the two shafts

Pin Bush Coupling

Pin Bush Coupling is engineered for the power transmission applications, where limited misalignment between the driven and the driver shafts occur. It is a package of sophisticated construction and high torque transmitting capacity at higher speeds and is capable of absorbing shock loads.

Tyre couplings

Tyre couplings have a rubber or polyurethane element connected to two hubs. The rubber element transmits torque in shear. Reduces transmission of shock loads or vibration. High misalignment capacity. Easy assembly w/o moving hubs or connected equipment.

Spider Elements

Our clients can avail from us a highly advanced range of Spider Element for all type’s of Coupling. Manufactured as per the latest industrial standards, these products are ideal for all types of steel rolling, lifting, forging, petroleum and other large equipment ,mechanical equipment , hydraulic equipment and transmission.

Spider Elements

Our clients can avail from us a highly advanced range of Spider Element for all type’s of Coupling. Manufactured as per the latest industrial standards, these products are ideal for all types of steel rolling, lifting, forging, petroleum and other large equipment ,mechanical equipment ,